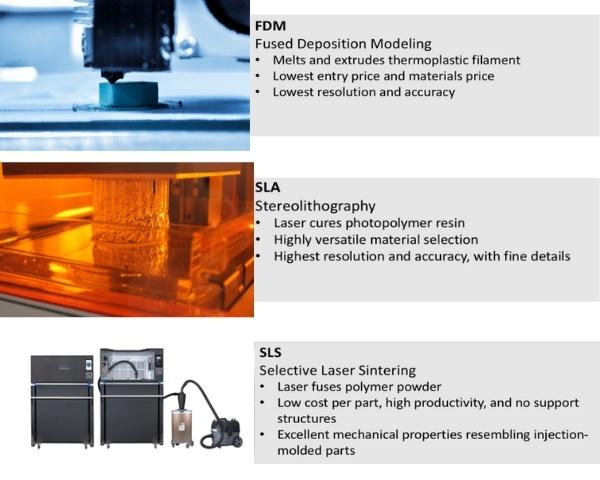

3D Printing Technologies: FDM vs SLA vs SLS

Over the last few years, high-resolution 3D printers have become more affordable, easier to use, and more reliable. As a result, 3D printing technology is now accessible to more businesses, but choosing between the various competing 3D printing solutions can be difficult.

Which technology suits your particular application the best? What are the differences between the three most established 3D printing processes: fused deposition modeling (FDM), stereo lithography (SLA), and selective laser sintering (SLS)?

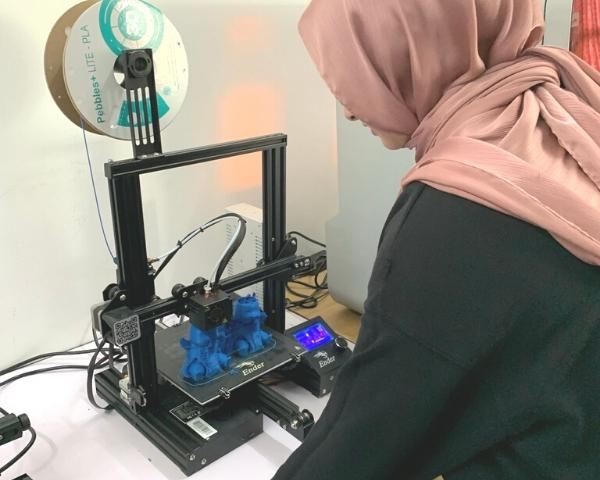

Fused Deposition Modeling (FDM)

FDM is the most generally used form of additive manufacturing method. FDM 3D printers build parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area. It works by extruding a thermoplastic polymer through a heated nozzle and depositing it on a build stage. FDM machines are the most affordable among all kinds of 3D printers. It is suitable for individuals that do not have a large budget. The FDM technology is quick, a perfect technique to manufacture a 3D project at home. However, this technique won’t allow you to reach professional or industrial results.

Stereolithography (SLA)

SLA was the world’s first 3D printing technology. It was invented in the 1980s, and is still one of the most popular technologies that suits best for professionals. SLA-resin 3D printers use laser to cure liquid resin into hardened plastic in a process called photo-polymerisation. In SLA 3D printing, liquid resin is cured by a highly-precise laser to form each layer. With SLA techniques, finer details and higher reliability can be achieved to repeatedly achieve high-quality results. As a result, SLA 3D printing is known for its fine features, smooth surface finish, ultimate part precision, and accuracy.

SLA 3D printers create chemical bonds by cross-linking photopolymers across layers, resulting in fully dense, watertight and airtight parts. These bonds provide high degrees of lateral strength. Hence, SLA is most ideal for engineering and manufacturing applications where material properties matter.

Selective Laser Sintering (SLS)

SLS is able to produce strong, functional parts, which makes it the most common additive manufacturing technology for industrial applications. It is also highly trusted by engineers and manufacturers across different industries. SLS is ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-moulded parts. It uses a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures. SLS printers are usually big in size and costly, hence it is usually reserved to professional companies and online 3D printing services.