3D Printing: The new sustainable manufacturing method

Manufacturers worldwide are starting to increase usage of 3D printing in their manufacturing processes to fulfill complex and strict designs with a sustainable approach, while also increasing cost-effectiveness. In a market that is increasingly demanding and unpredictable, 3D printing gives manufacturers the ability to be flexible in meeting changing needs quickly.

Reduce and minimise waste

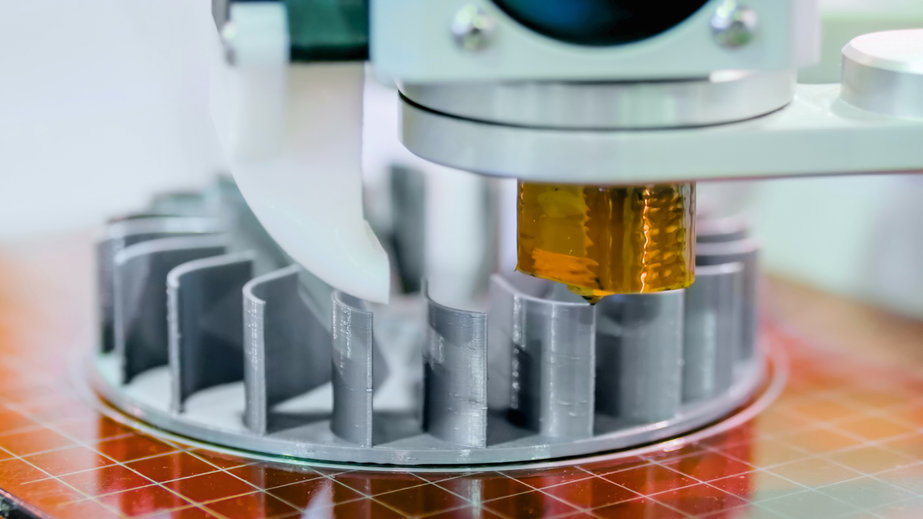

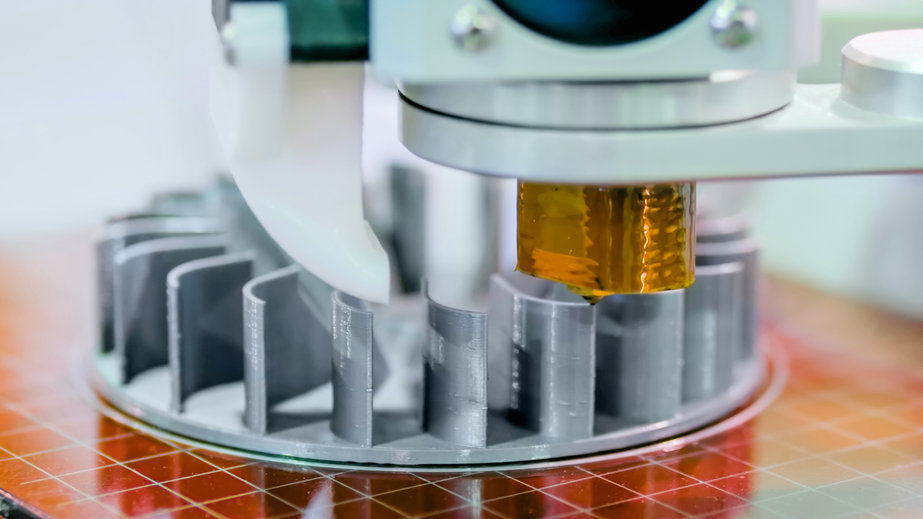

According to a European Commission study, 90% of raw materials usage can be reduced by the year 2050 by adopting additive manufacturing. 3D printing technology allows minimum waste in the manufacturing process as all parts of models, prototypes, tools, moulds and final products are made in one single process. Instead of sculpting a large piece of metal or plastic, 3D printing precisely constructs the item layer by layer.

3D printing is also a more environmentally-friendly option for manufacturing compared to traditional manufacturing as the materials used, other than natural raw materials, are converted from waste. For example, used single-use plastics such as water bottles are able to be converted into raw material for 3D printing. Natural materials such as spent coffee grounds, algae, and cellulose are raw materials that can be used in 3D printing as well.

This technology meets the principles of circular economy through designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. Thus, adopting this technology is the way of the future.

Innovations of manufacturing equipment

3D printers are able to replace several pieces of traditional manufacturing equipment by printing different varieties of parts and products with just one printer. By adopting 3D printing techniques, factory size can be reduced as less machines and equipment are needed. Manufacturers are also able to reduce costs with the decreasing need for logistics by producing locally, hence fewer carbon emissions.

Looking at the benefits and abilities of 3D printing, we are not far from fully converting from traditional manufacturing to additive manufacturing. While materials, technology, and industry practices are factors to be considered and improved, 3D printing indeed is a great alternative to traditional manufacturing, in terms of long-term sustainability. Contact us to find out how your business can benefit from adopting 3D printing too!