3D Reverse Engineering - How it works

While 3D printing turns digital designs into physical parts, 3D reverse engineering, as its name suggests, creates digital designs from a real object part. In manufacturing, an accurate 3D scanner with reverse engineering method enables the production or reproduction of physical objects by using the physical object itself as the guide. With this, designing 3D printed parts that fit perfectly into any existing product can be achieved.

3D Scanning for 3D Reverse Engineering

Among all the methods used for collecting base dimensional measurements, 3D scanning is the most effective and efficient method. It allows you to get an exact image of an object in virtual reality. 3D scanners measure complex objects very quickly with more effective time cost for design workflow since real object references are involved. With a 3D scanner, you can capture and modify physical shapes of an object, then produce a mesh. You will then be able to design 3D printed parts that are complex or asymmetric that might otherwise be difficult to build.

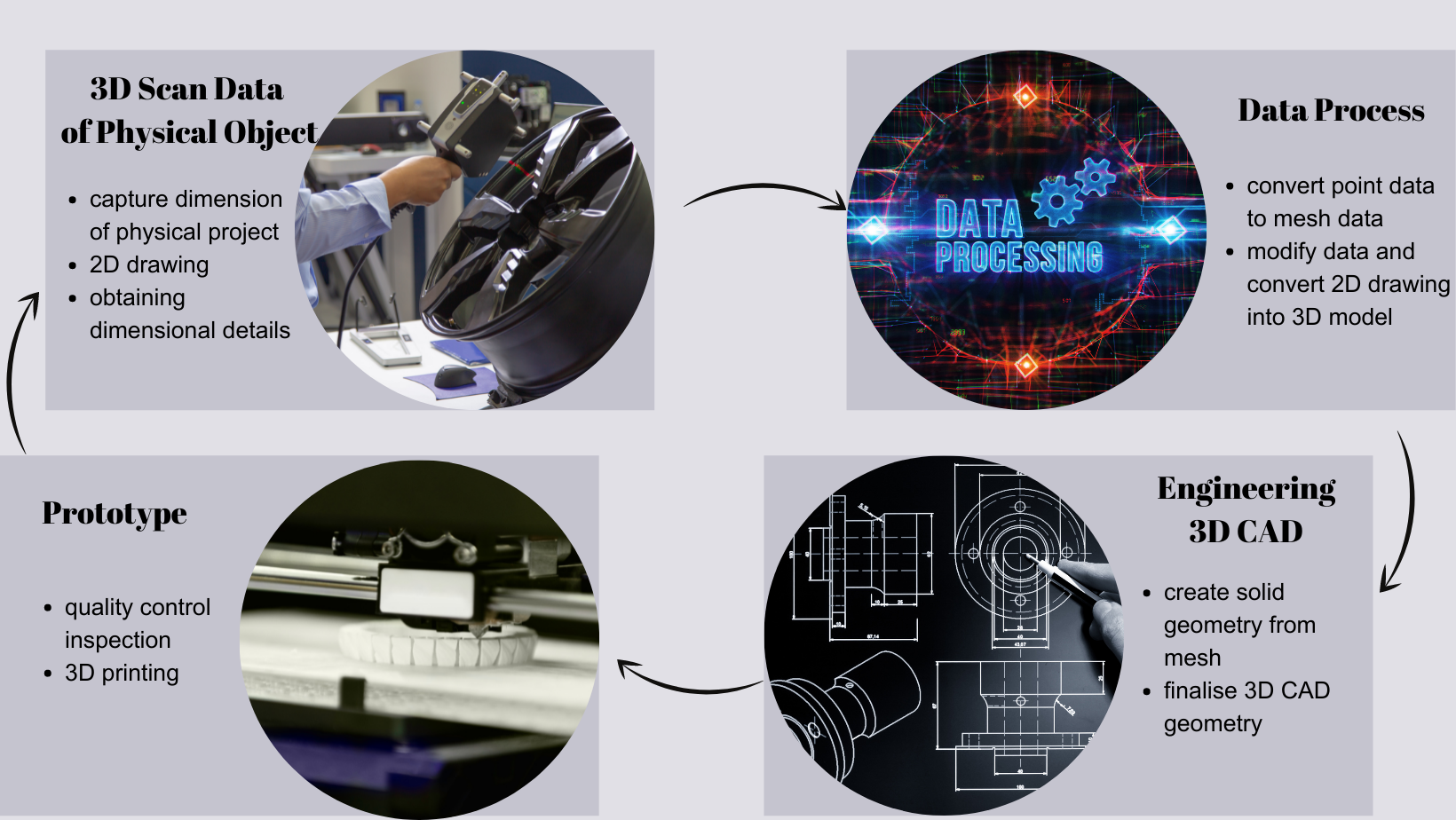

The process of reverse 3D printing:

How is 3D Reverse Engineering beneficial?

Having knowledge of the original designed object is crucial as every layer and piece of the object has to be disassembled in order to construct. Even so, there are no limitations on size for 3D scanning. Every part of an object, no matter tiny or huge, is able to be scanned using different kinds of 3D scanners.

With 3D Reverse Engineering, you are able to redesign an object part without manufacturing defects. By inventing with 3D reverse engineering, it saves up a lot of time and resources, which allows business owners and manufacturers an added advantage in the market.

You are also able to develop components that connect new parts to old parts, even if the production of a component has been shutdown due to the subsequent changes in technology. In short, reverse engineering allows you to regain design data of long-discontinued products that might be produced before computer-aided design and digital file storage were used.

There are so many opportunities and potential in adapting the 3D reverse engineering technique. New to 3D reverse engineering? Contact us to know more about 3D reverse engineering, we will be happy to assist.